Simulations involving THESEUS‑FE

As part of our business we offer engineering services for all kinds of simulations using THESEUS‑FE.

You may book one of our engineers for simulations in the following fields:

- Cabin climatization

- Thermal comfort of passengers

- Underhood Thermal Management

- Thermal Management of electronic components

- Paint-drying oven model calibration and simulation

- E-Coating model calibration and simulation

Individual software development and adjustments

One of our major strengths is our flexibility regarding custom software solutions. With the strong backbone provided by our thermal solver THESEUS‑FE, we can offer individualized features such as:

- tailored GUI features for individual pre- and post-processing tasks

- user subroutines, e.g. for advanced convection models or comfort models

- new interfaces for coupling with other solvers

- custom specialized solvers for related engineering problems

Model Creation

The first step when creating models for any kind of FE-simulation is the preparation of the CAD data and the mesh creation. For this process we use the most advanced software tools and interfaces currently available on the market. Our model creation engineers are highly trained for any kinds of modelling task arising for simulations:

- 2D shell meshing, e.g. for mechanics simulations or for THESEUS‑FE

- 3D volume meshing, e.g. for THESEUS‑FE E-Coating or CFD solvers

- all kinds of joining technology (contacts, weld spots, rivets, screws, ...)

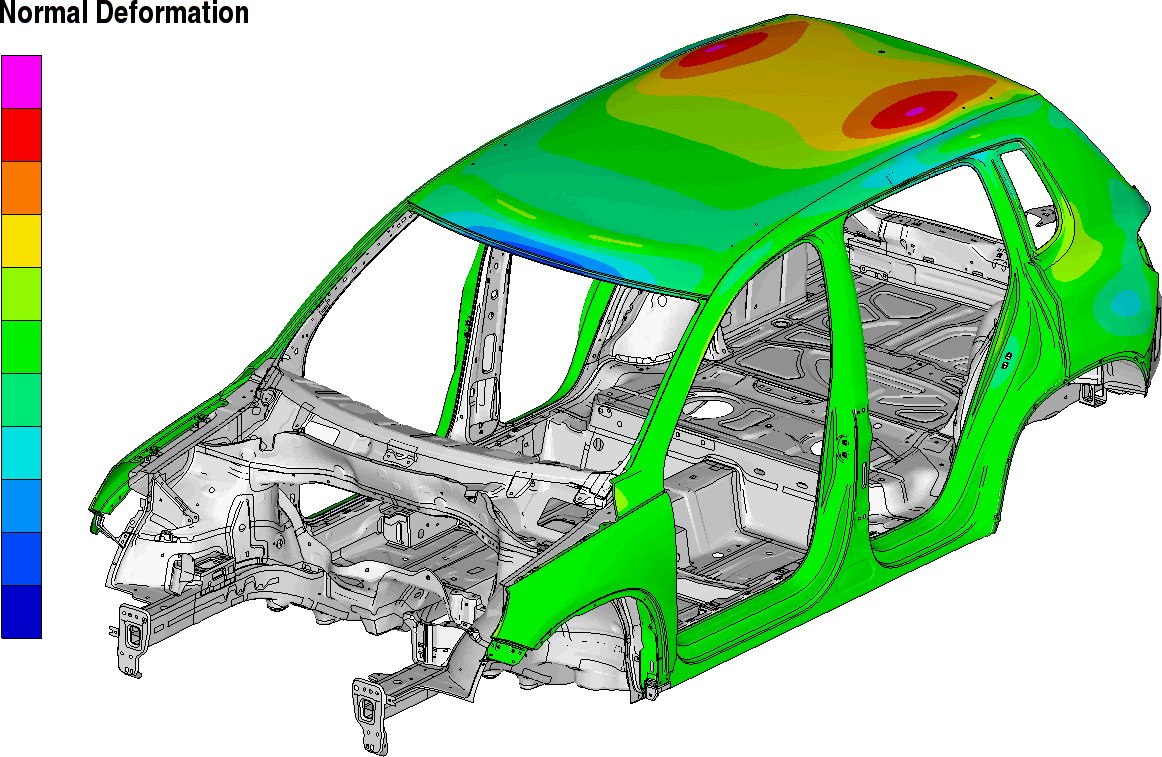

Mechanical simulations

Besides experts for thermal and CFD simulation, our team also includes experts in the field of mechanics simulations.

For mechanical simulations our site mostly relies on the tool Abaqus FEA.

We can offer nearly any kind of simulation in this domain, including:

- thermo-mechanically coupled simulations (using detailed temperature results from THESEUS‑FE)

- custom user-subroutine programming (mainly sophisticated user-materials in form of UMAT/VUMAT)

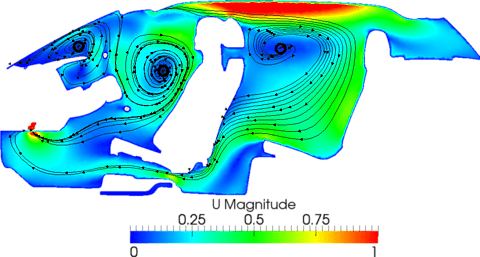

CFD simulations

Numerical flow simulation is becoming increasingly established, even for the analysis of complex phenomena such as multi-phase flows and fluid-structure interation.

Simulation results often offer an insight into flow behaviour that is inaccessible when relying on standard measurement techniques.

Our specialists will find the best combination of tools to crack your flow problem.

We offer CFD simulations with Star-CCM+ or OpenFOAM, both of which can be coupled with THESEUS‑FE for co-simulation runs as necessary:

- highly-detailed paint-drying oven temperature prediction for planning new facilites

- fine-grained cabin ventilation & local comfort prediction

- underhood and underbody thermal management

Measuring of mechanical material parameters

Using correct material properties is of utmost importance when doing numerical simulations. They are the basis for meaningful simulations to produce results faithfully recreating real-world behaviour.

In our in-house laboratory boasts a selection of mechanical measuring instruments, for example

- DMA instruments (dynamic mechanical analysis)

- DSC instruments (differential scanning calorimetry)

- Rheometer

- Dilatometer

These are mainly used for but not limited to measuring the proper input material properties for our user-material subroutine for adhesives.