Our software portfolio THESEUS‑FE consists of several professional simulation tools for solving engineering problems related to thermal management problems and automotive paint shops.

Historically, the core of THESEUS‑FE is deeply rooted in simulating all kinds of thermal processes.

Typical application cases range from simple conductive heating of individual parts to highly sophisticated multi-physics simulations coupling conductive, convective and radiative effects.

Initially designed mainly for use in the automotive, transportation and aerospace industry, the core thermal solver has successively been extended to be widely applicable for all domains where thermal behavior needs to be investigated.

The traditional part of THESEUS‑FE consists of

- the classical THESEUS‑FE thermal module

- module FIALA-FE, a thermophysiology model for simulating the thermal balance of the human body and evaluating thermal comfort

Over the years, more application cases arose which demanded highly specialized solutions.

Building on our expertise gained over decades of solving thermal problems, we developed in close cooperation with our automotive customers efficient and robust solutions for simulating automative paint shop processes.

In this context the following tools complete the THESEUS‑FE portfolio:

- THESEUS‑FE E-Coating module to simulate electrocoating of car bodies

- THESEUS‑FE Oven module to simulate hot air drying of coated car bodies in industrial drying facilities

- a special user material subroutine for Simulia Abaqus to model the viscoelastic behavior of adhesive materials for joining car parts

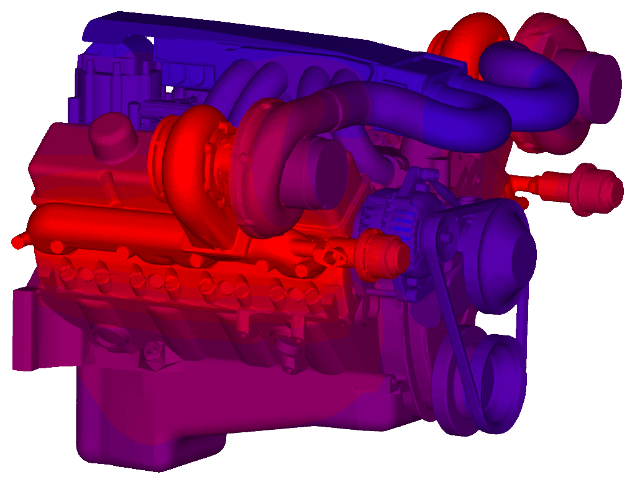

Heat Transfer Analysis

The classical THESEUS‑FE module is a full-featured thermal solver capable of simulating all major modes of heat transfer. By coupling the various physical effects of heat conduction, convection and radiation it allows the effective solution of nearly all thermal management problems occuring in practice.

Whenever the transient thermal development of any component part is of concern, THESEUS‑FE is the proper tool to simulate it. THESEUS‑FE makes use of established Finite-Element methods to treat thermal conduction in solids - supplemented by various models for simulating radiative and convective heat loads.

The heat transfer solver is complemented by the FIALA-FE module for virtual human thermal simulation. It allows accurate predictions of thermal comfort of passengers in a given environment. For cases requiring the detailled modelling of fluid flow patterns, we provide the Coupler module for performing co-simulation with major CFD simulation tools. With these packages even the most complex engineering challenges are easily tackled.

Find out how THESEUS‑FE can be applied to solve complex heat transfer problemsHuman Thermal Comfort Simulation

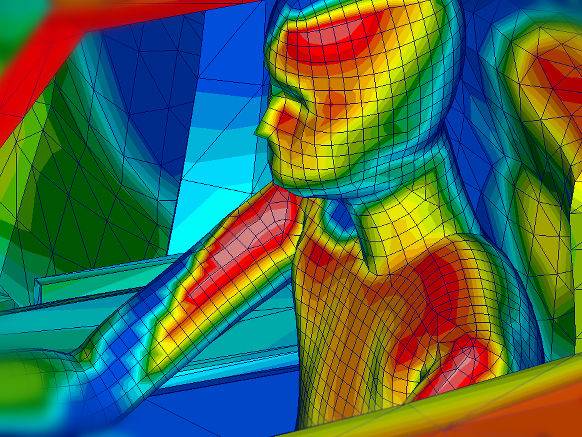

The FIALA-FE module is one of the many unique features of the THESEUS‑FE portfolio. It is a virtual model for simulating human thermophysiology and evaluating thermal comfort sensation.

FIALA-FE takes into account the internal heat production of the body metabolism, excess heat from physical labour, and all significant thermoregulatory effects such as shivering, sweating and respiration. Combined with external environmental conditions such as solar radiation or convective heat exchange it can be used to analyze the transient development of human body temperatures.

Furthermore it can be used to predict the comfort sensation when a human is exposed to certain environmental conditions. Typical use cases are the evaluation of thermal comfort (too hot, too cold, comfortable, ...) inside vehicle cabins or air-conditioned offices. A large selection of widespread comfort evaluation indices are available for rapid and intuitive interpretation of the simulation results.

Read more about assessing human thermal comfort using THESEUS‑FEPaint Dryer Simulation

(Source: BMW Group PresseClub)

Body coating and finishing in the automotive business has become a highly complex process. The bare metal of the car body surface is covered with several additional layers, including an ultra-thin corrosion protection layer, a filler to cover irregularities and protect against environmental influences, and finishers to yield a unique visual appeal.

Between the application of some of these layers, a paint-drying oven is used to cure and harden the material. It is not uncommon to use 4-5 different drying facilities during the overall process.

THESEUS‑FE OVEN simulates the transient temperature development inside such a paint-drying oven. The thermal results are directly used to ensure that optimal baking time frames are met to guarantee optimal paint layer properties. Additionally, the temperature solution is as an input to a subsequent structural mechanics analysis for predicting mechanical deformations occuring due to the heating and abrupt cooling of the car body.

See how THESEUS‑FE is applied to computationally analyze car paint-drying processesE-Coating Simulation

Electrophoretic Deposition Coating (EDC) or short E-Coating has become a standard process in car manufacturing. It is usually used to apply a corrosion resistance layer to the car body frame. The pre-treated car body is dipped into a tank containing a coating emulsion based on polymers. A static electric field causes migration of the ionized paint particles in the emulsion and subsequent deposition on the metallic car body. The result is a thin and uniform protection layer extending all the way into recessed corners and cavities.

With THESEUS‑FE E-Coating the coat deposition and buildup can be fully simulated. Problematic areas where the protection layer remains too thin are quickly identified and counter-measurements tested with minimal turnaround times.

The simulation of the coat quality contributes to minimizing the need for cost- and time-intensive measurements on physical prototypes.

Read more about simulating E-Coating paint deposition processes for car body corrosion protection using THESEUS‑FEViscoelastic Material Model for Polymer Adhesives

For simulating the viscoelastic behavior of adhesive materials used in connecting structural car body parts, a special user-material subroutine for use in Simulia Abaqus FEA is available. It models the unique mechanical behavior of adhesives and comprises a viscoelastic material model, a reaction kinetics model for curing of adhesives and special reporting functionality.

It is generally activated during a deformation analysis within Simulia Abaqus FEA using temperature results from the THESEUS‑FE OVEN module as input.

Inform yourself about the sophisticated viscoelastic material models for polymeric adhesives